Detection Technologies:

Underground oil leak detection systems leverage diverse technologies to monitor for signs of leakage, each with its unique capabilities and applications:

Hydrostatic Monitoring: This method relies on pressure sensors installed within the tank to detect variations caused by the presence of oil or water. A decrease in pressure may indicate an oil leak, prompting the system to trigger alarms for immediate action.

Acoustic Monitoring: Acoustic sensors listen for distinctive sound patterns associated with fluid movement within the tank. The emergence of anomalous noise signatures can signal the presence of leaks, prompting the system to initiate response protocols.

Electronic Sensors: Electronic probes measure changes in electrical capacitance underneath the tank, which can occur in the presence of oil. By continuously monitoring capacitance levels, these sensors can detect even minor leaks with precision.

The first two techniques are less efficient than the third one.

Components of Oil Leak Detection Systems:

Oil leak detection systems comprise several integral components, each contributing to the system's overall functionality and reliability:

Sensor Network: A network of sensors, strategically positioned within and around the tank, forms the backbone of the detection system. These sensors continuously monitor various parameters, including pressure, sound, and conductivity, to detect deviations indicative of leaks.

Control Unit: The control unit serves as the central processing hub, receiving data from sensors and executing programmed algorithms to analyze and interpret the information. In the event of a suspected leak, the control unit triggers alarms and initiates response protocols to mitigate the potential risk.

Communication Infrastructure: Many modern oil leak detection systems feature robust communication capabilities, allowing real-time data transmission to monitoring centers or designated personnel. This facilitates prompt decision-making and intervention in the event of an emergency.

Operation and Maintenance Protocols: Ensuring the optimal performance of underground oil leak detection systems requires adherence to rigorous operation and maintenance protocols.

Regular Testing: Periodic testing and calibration of sensors are essential to verify their accuracy and responsiveness. This may involve simulated leak scenarios or performance evaluations conducted according to industry standards.

Routine Inspections: Scheduled inspections of system components, including sensors, wiring, and control units, are imperative to identify and rectify any potential issues promptly. Routine maintenance tasks, such as sensor cleaning and equipment calibration, should also be performed as part of a comprehensive maintenance regimen.

Operator Training: Adequate training of personnel responsible for operating and maintaining oil leak detection systems is paramount. Training programs should cover system operation, troubleshooting procedures, and emergency response protocols to ensure swift and effective intervention in case of a leak or system malfunction.

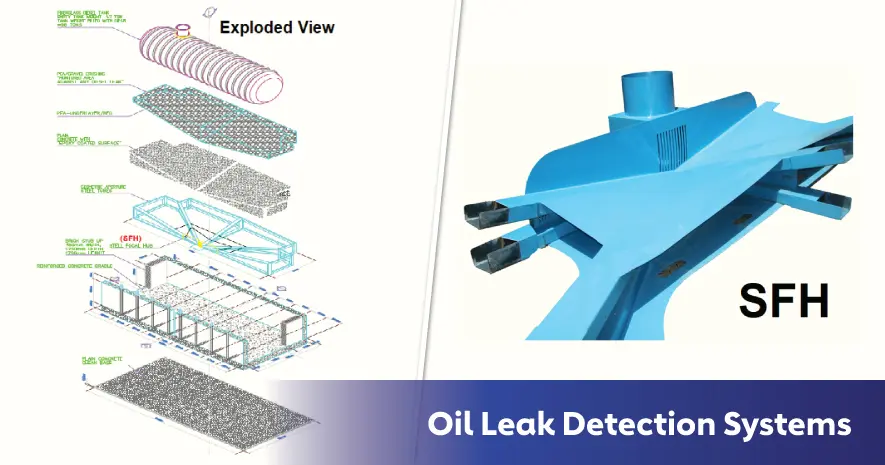

M&I Est. Flagship Innovation of oil leak detection system:

The Steel Focal Hub (SFH), is a cutting-edge solution with unparalleled features:

1. Centralized Monitoring: All monitored areas converge to a single point, directing spills towards the detection chamber for efficient surveillance.

2. Rapid Detection: The SFH boasts an efficient detection technique, requiring only minimal oil drips to activate the system. This is achieved through the carefully designed collecting aperture and angles to achieve steepest path.

3. Comprehensive Detection: The system can identify stormwater diffusion independently through a dedicated probe for this purpose.

4. Adaptive Immersion: Even during deluge storms or massive oil leaks, the detector remains buoyant, floating at the oil or water surface respectively. The detection function remains unaffected, ensuring continuous monitoring.

5. Accessible Maintenance: The 250mm diameter accessible well allows for easy inspection, cleaning, and measurement of oil height within the detection chamber.

6. Efficient Cleanup: Following oil detection, a small submersible pump can be inserted into the detection well to remove accumulated oil or stormwater diffusion.

7. Immersive Data: The control panel provides easy access to total immersion hours, offering insights into the duration of oil leaks.

SFH-based oil leak detection system is suitable for various environments including military bases, hospitals, hotels, factories, and oil stations. We offer comprehensive design, manufacturing, and installation services both domestically and internationally.

8. More economical comparing with capacitive cable zigzag, which is usually laid over a vast area underneath oil tank.

9. Using SFH technique, allows monitoring every squared inch underneath oil tank; Whereas, capacitive cable zigzag triggers only if oil drip falls directly on it! If leak took place within areas between zigzag shape, oil leak can never be detected unless after enough time of accumulation of oil leak or side spillover.

Conclusion:

Oil leak detection systems for underground tanks are vital for environmental protection and operational efficiency. Mastering and Innovation Est. (Etqan Wa Ibtekar in Arabic) has pioneered advancements in this field with competitive prices comparing to its rivals, optimal coverage, leveraging IoT, smart sensors (oil & water), and advanced materials to provide state-of-the-art leak detection solutions, by harnessing SFH with steepest design to focus leaks directly by gravity toward detection chamber slits and offering real-time monitoring capabilities, ensuring the highest level of safety and compliance for underground storage tank stipulations.

Recent News

AWAM Magnetic Float Level Switch: A Benchmark in Excellence

August 17, 2024